Fabrication know-how

Discover know-how/tips/cautions shared by aligner fabricating experts

Thermoform

It explains know-how for thermoforming, cleaning and packing.

Thermoforming process

Thermoforming > trimming > polishing&cleaning

Select forming equipment

Minimum specification: pressure 4 bar or more

Item | Pressure forming | Vacuum forming |

Pressure | 4-6 bar | 4-6 bar |

Principle |  |  |

Strength and weakness | Expensive High forming quality | Cheap Low forming quality |

Sheet selection criteria

Clear aligner is a device for oral use, and the sheet must be a certified medical device. Medical device certified products have no problem with treatment. The difference between high and low prices is due to difference in product characteristics such tensile strength depending on raw materials and manufacturing processes. Products with good characteristics are expensive products, and have positive effects such as wearing comfort and shortening the treatment period.

There are 3 types of sheet depending on the thickness of the product.

Item | Soft | Medium | Hard |

Thickness | 0.5mm (0.02inch) | 0.625mm (0.025inch) | 0.75mm (0.03inch) |

Image |  | ||

Tooth movement range | 0.6~1.0mm | 0.4~0.6mm | 0.2~0.4mm |

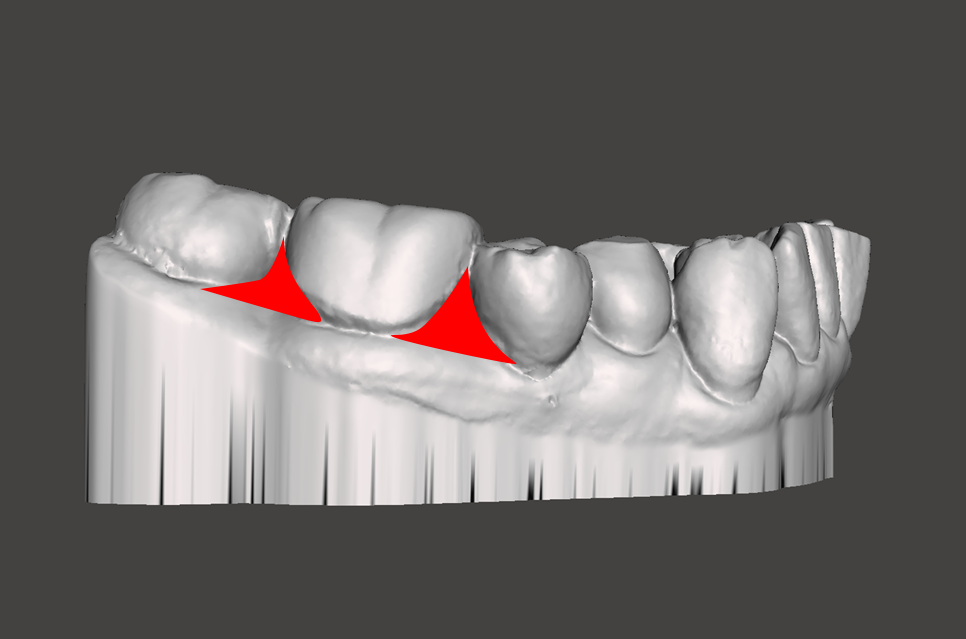

Blockout

In case sheet does not fall out by undercuts, or in case sheet is torn by sharp edges,

it is task of supplementing the model with resin for blockout or with heating-resistant material.

A typical case of blockout

Thermoforming method

Ensure that the height of model being molded is only up to the gums that will be used as devices.

If it is too high, the sheet stretches a lot and becomes thin, and a device of uniform thickness cannot be made.

Use a height-adjustable equipments, or adjust the base height carefully printing.

Gums are high | Adjusting to fit gums | Adjusting to fit gums |

Adjust pellet | Print model low | |

|  |  |

|  |  |

Precautions when removing devices

To prevent deformation or tearing of the device, remove unnecessary parts as much as possible in advance, and do not remove them all at once, but remove the rearmost molar part little by little.

Trimming

Please cut 2~4mm below the margin using curved scissors.

TIP : Use curved scissors. You can easily cut to fit the arch line using curved scissors.

Trimming area

Along margin line | Straightly 2~4mm below margin line |

|  |

Strength and weakness Little force transmitted No foreign body feeling | Strength and weakness Lot force transmitted because there are many parts to wrap May feel foreign body |

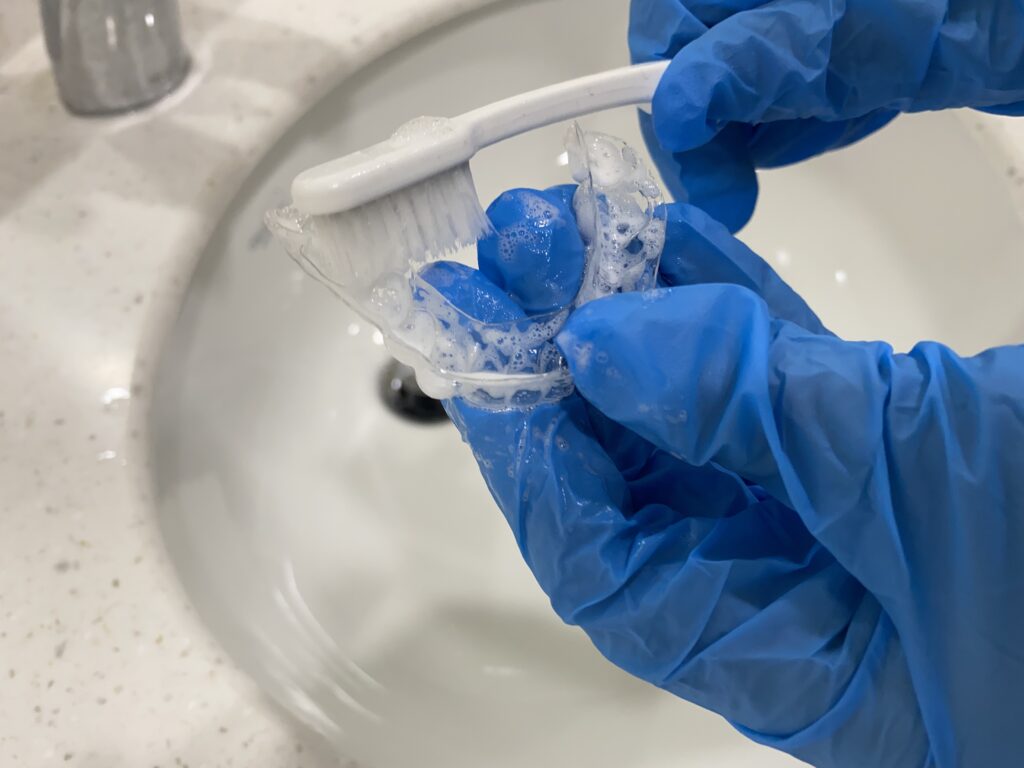

Polishing & cleaning

Smoothly round the sharp part of the cut section, clean to remove foreign objects and bacteria.

TIP :

When polishing with handpiece, it must move in one direction along the direction of rotation of the wheel.

When cleaning with air, be careful that the device may be deformed if too strong force is applied.

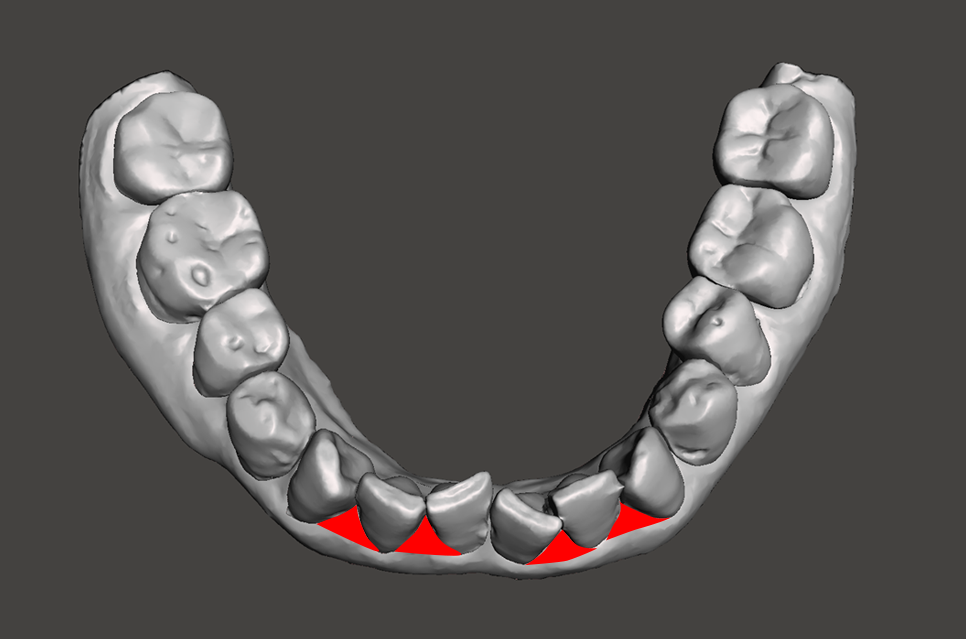

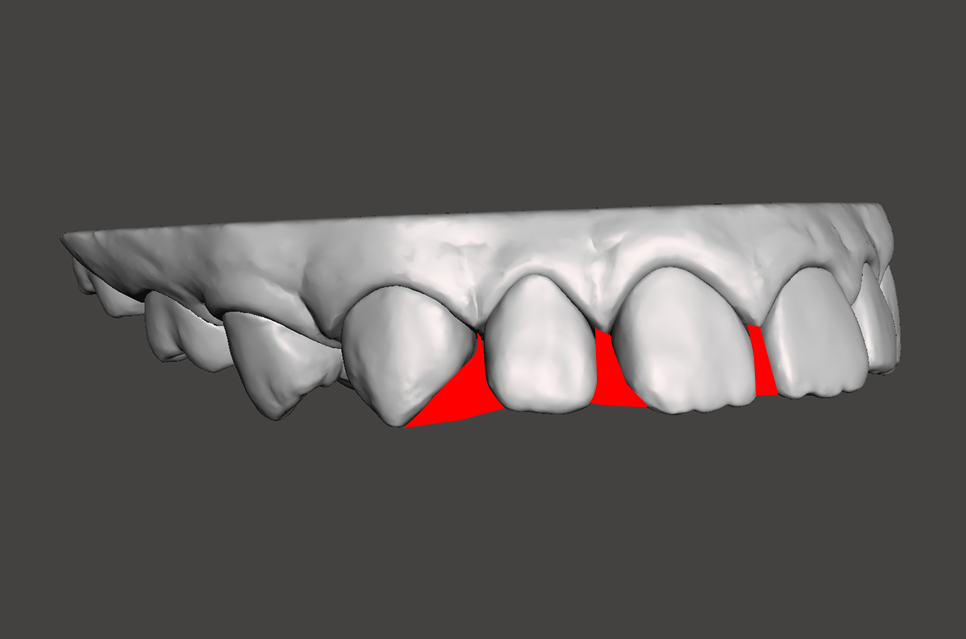

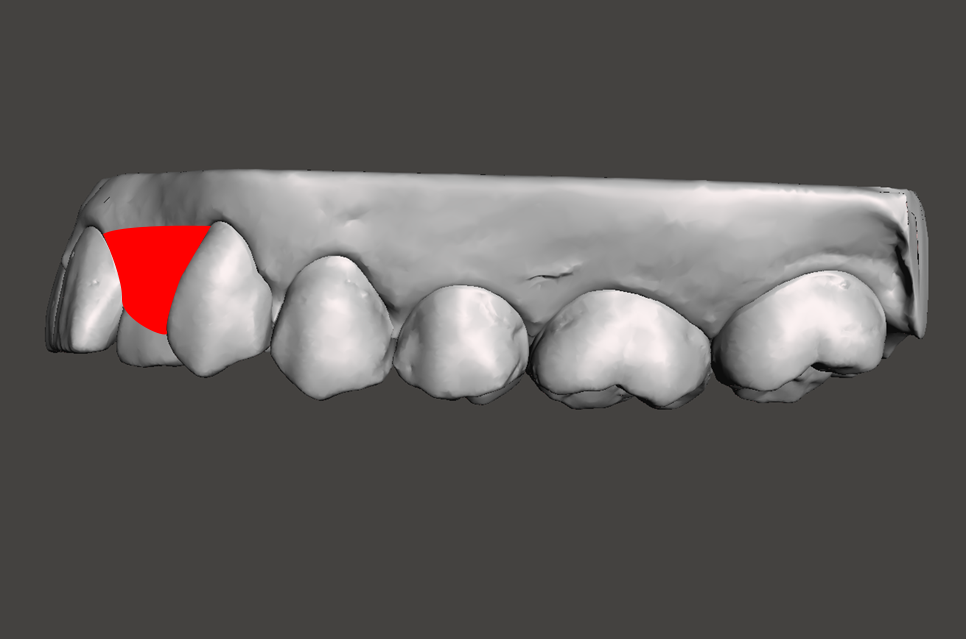

Accuracy standard for full arch